Revolutionising Pipeline Commissioning Through Vacuum Purging

The natural gas industry is under increasing pressure to reduce methane emissions and improve environmental stewardship.

Traditional pipeline commissioning methods, which rely on venting natural gas to displace air or nitrogen, have long been accepted for safety but are now recognised as contributing to greenhouse gas emissions and air pollution. To address these challenges, National Grid has recently conducted a field demonstration of a portable vacuum purging system in Yaphank, New York. Vacuum purging evacuates air from pipelines before introducing gas, ensuring safe conditions while also offering significant emissions reductions and better operational efficiency compared to conventional practices.

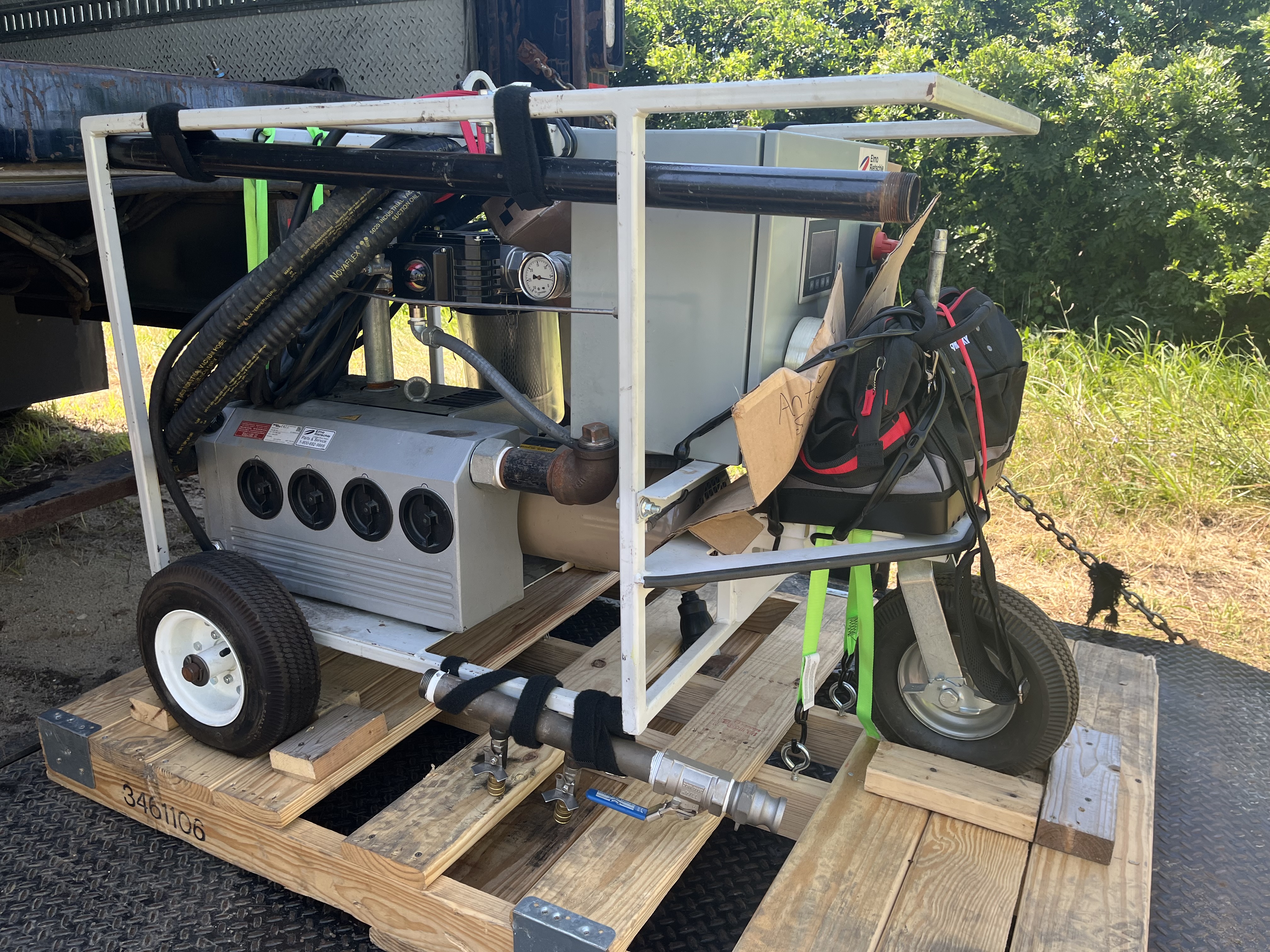

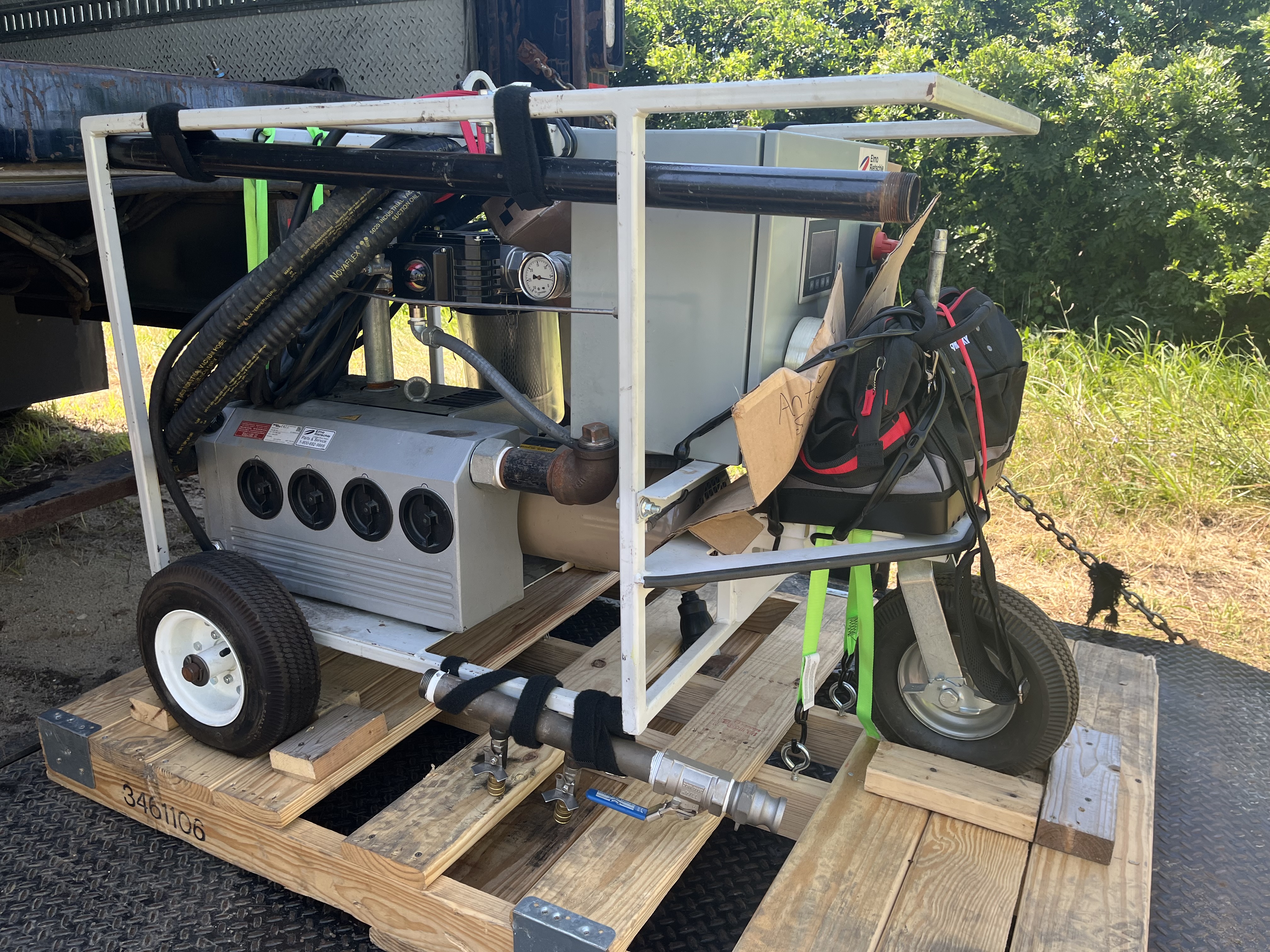

The research and development behind vacuum purging were spearheaded by Operations Technology Development (OTD). OTD is a gas research consortium that National Grid has been a member of for over a decade. OTD conducted a desktop analysis which validated the method's technical feasibility and environmental value. In the next phase, OTD developed a prototype for a portable vacuum purging system and conducted field tests around the country on new pipe installations. These findings have spurred further development and industry interest, positioning vacuum purging as a commercially viable solution for utilities seeking to meet regulatory and sustainability goals.

The field demonstration conducted on Long Island deployed OTD's portable vacuum purge prototype to evacuate air from a new 2000' 8" main. The project team worked closely with Process Safety to develop a rigorous risk assessment and mitigation plan to ensure that all potential safety concerns were addressed. The demonstration not only reduced methane emissions by an estimated 93% compared to traditional methods but also cut the total operation time by more than half, exhibiting both environmental and operational benefits. The Yaphank demonstration also uncovered additional advantages, such as moisture removal from the pipeline. The successful execution of the pilot validated the method's reliability and scalability for broader adoption.

The vacuum purging pilot represents a transformative step for the gas industry, aligning operational practice with modern environmental and safety expectations. By achieving substantial reductions in emissions, time and resource use, vacuum purging sets a new standard for responsible pipeline commissioning. As utilities continue to innovate and adapt, this approach is poised to become a cornerstone of sustainable gas infrastructure projects in the years ahead. The portable vacuum purge developed by OTD is in the process of being commercialised and should see market entry in 12-18 months.

As this pilot focused on new pipes, National Grid's next step is to evaluate the effects of vacuum purging on existing pipe components and equipment, with a focus on stoppers (squeeze-offs, plugs, stopples, etc.) and fittings (tapping tees, valves, etc.). We also plan to establish a set of guidelines for our Operations teams to reference when planning a gas vacuum purging operation, enabling them to use this technology more widely in the future.