Europe’s largest diameter Vertical Shaft Sinking Machine launched at Tilbury, Essex

The Vertical Shaft Sinking Machine (VSM) begins work at the Tilbury site, part of National Grid’s Grain to Tilbury project

The VSM has the largest diameter ever of any VSM in Europe, and the largest supplied by Herrenknecht, with works being delivered by Ferrovial BEMO JV

Named after Verena Holmes, a pioneering British mechanical engineer and the first female member of the Institution of Mechanical Engineers

Grain to Tilbury is part of The Great Grid Upgrade, the largest overhaul of the electricity grid in generations

The pioneering Vertical Shaft Sinking Machine (VSM), named “Verena”, after Verena Holmes, a pioneering British mechanical engineer, has begun operations at National Grid’s Tilbury site.

This marks a new chapter in the delivery of the Grain to Tilbury electricity upgrade project, a critical part of National Grid’s The Great Grid Upgrade, designed to future-proof the UK’s electricity transmission network. The project will replace the existing 1960s Thames Cable Tunnel between Tilbury and Gravesend, which has reached the end of its useful life. It is part of the upgrade to the country's electricity network, helping to connect more affordable sources of home-grown and renewable energy to homes and businesses.

Ferrovial BEMO JV has been awarded the contract to build a 2.2km-long high-voltage (400kV) cable tunnel, with the VSM designed and built by Herrenknecht AG. This purpose-built approach represents a significant innovation for UK shaft construction, offering improved safety, speed, and environmental performance.

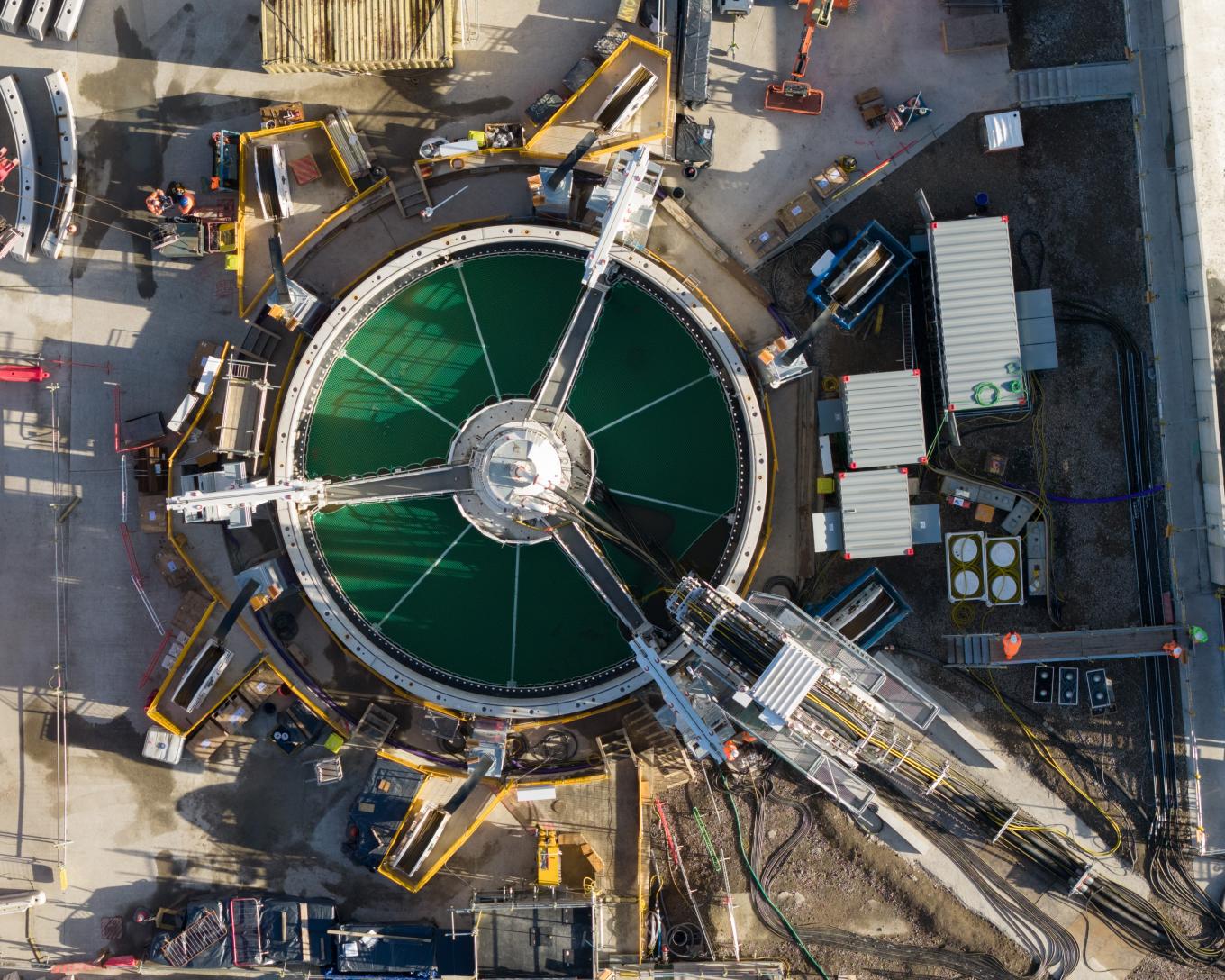

The VSM has now been deployed to construct the 15m internal diameter shaft at Tilbury, reaching a depth of just over 48 metres. Once complete, a second shaft will be constructed at the project’s Gravesend site.

The VSM is remotely operated from the surface and removes the need for operatives to enter the shaft during construction. The VSM cutting drum operates within a water-filled shaft, eliminating the need for groundwater lowering or treatment. The shaft is carefully lowered from the surface as the excavation progresses. This all helps to ensure safe, efficient progress through challenging geology.

Mark Farmer, Project Director for National Grid, said:

The Grain to Tilbury project is helping to future-proof the UK's electricity network. The launch of the Vertical Shaft Sinking Machine marks a major milestone for the project. Through collaboration and innovation, this technology is helping to deliver resilient infrastructure under the Thames, securing reliable electricity for the decades ahead.

Borja Trashorras, Project Director, Ferrovial BEMO JV, said:

Launching Europe’s largest diameter Vertical Shaft Sinking Machine at Tilbury is a milestone achievement for our team and for UK infrastructure. This technology allows us to deliver the Grain to Tilbury project with enhanced safety, efficiency, and environmental performance. We’re proud to be working in partnership with National Grid and Herrenknecht to bring this pioneering solution to life, helping to future-proof the electricity network for generations to come.

Ulrich Schaffhauser, Member of the Board of Management, Herrenknecht AG, said:

We’re honoured to be a trusted partner of Ferrovial BEMO JV and National Grid in this milestone project. Delivering Herrenknecht’s largest-ever VSM for the shafts, and the Mixshield TBM for the cable tunnel, supported by essential equipment and dedicated service, we proudly contribute to the project’s successful completion.