The 29m high gasholder in Great Yarmouth has been part of the town’s skyline since it was built in 1884. However, specialist condition assessments show that works are needed to secure the long term future of this Grade II Listed structure.

Following extensive consultation with the local community and Historic England, National Grid’s plan for the site was given planning permission and listed building consent by Great Yarmouth Borough Council in April 2024. National Grid owns the former gasworks site at Admiralty Road, but gasholders are no longer used as part of the national gas system.

National Grid has a national programme agreed with OFGEM to bring redundant sites such as these back into use, but the Grade II Listed status of the Victorian gasholder and its condition requires a different approach. Following detailed technical assessments it was agreed that the tank at the bottom of the gasholder should be removed and the large visible frame should then be refurbished in-situ at the site. This will open up the site for new uses and secure the long term future of the gasholder and its place on the local skyline.

Water removal

Our specialist contractors, Erith, started by removing the water in the bottom of the gasholder. This was pumped out, treated on site and discharged into the local sewer under a consent from Anglian Water.

Before work started to remove the tank any oil and sludge inside the tank was removed.

Steel cutting

Once the water, oil, sludge and other debris was removed, the tank was dismantled. This involved cutting the cast iron structure using a range of equipment. Some of the metal has been stored on site for possible re-use in the future.

This first part of the work began in September 2024 and was finished in May 2025.

You can watch a film about the first stage of the works here:

You can also watch a timelapse here:

Now the tank has been removed detailed design work is underway to plan the refurbishment works. These works are likely to include:

- the removal of old paint and cleaning of the frame;

- structural repairs to the cast iron frame as required; and

- painting of the frame

We will provide more information on this when the design stage is complete. We expect this stage of works to start in late 2025/early 2026 and be complete by the end of 2027.

We're an approved Client Partner of the Considerate Constructors Scheme

More information on the site and community

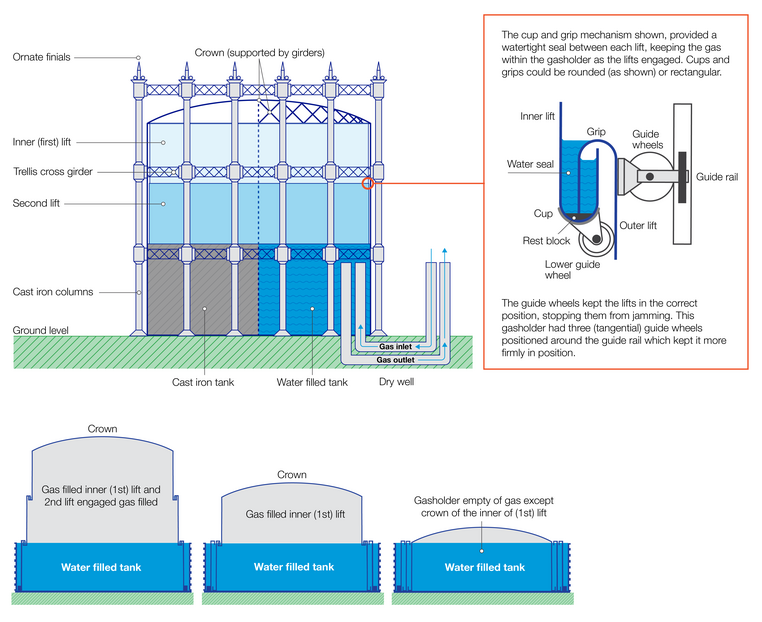

Gasholders were used to store gas until it was needed by homes and factories. They were first used to store gas made from burning coal at local gasworks but were also used to store natural gas when this started to be used.

As gas was used the tanks fell and as they re-filled, usually at night, they rose again. Gasholders are no longer used as part of the national gas system as gas is now stored under pressure in a national network of pipes.

The Great Yarmouth gasholder had a water filled cast iron tank, and within this were two containers which stored the gas called 'lifts'.

The top lift was sealed at one end (the crown) and sat over the water. As the top lift filled with gas it raised out of the tank until it connected to the second lift which then filled with gas.

The lifts were guided by wheels which ran on rails on the inside of the columns, stopping them blowing over in the wind. Water in the tank and between the lifts provided a seal preventing the gas from leaking.

National Grid recognises that gasholders and gasworks are a part of our industrial heritage and how important it is to undertake historical recording at all gasholder sites.

At Great Yarmouth, Level Three Historic Building Recording is being undertaken given that the gasholder is Grade II Listed. This is available in the online record section of this website.

We have donated parts of the dismantled gasholder tank to the Fakenham Gas and Local History Museum, retained some material on site for future use and we are working on a project with the Time and Tide Museum to create a permanent sculpture at the museum using metal from the gasholder tank.

Site facts

The Great Yarmouth Gas Company started making gas from coal in 1824 on a site on the banks of the River Yare. The Admiralty Road site dates back to the 1860s when they needed to build a new gasworks on a nearby site. As the demand for gas changed during the day, the gas was stored in gasholders until it was needed by local homes and businesses.

The remaining gasholder at the site, known as Gasholder No. 172, is a column guided gasholder and dates from 1884

Including its finials, it is 29m high, has 14 cast iron columns and 52 lattice beams in the frame

It had a capacity of 385,000 cubic feet

The tank was made of rivetted cast iron plates with a diameter of 29.8m and contained two lifts which locked together to form one large space when it filled with gas

The gasholder was designed by R.P Spice and built by Samuel Cutler & Sons, originally on a different part of the gasworks before being re-located to its current position in 1885. The gasholder was decommissioned in the early 2000s.

Professor Russell Thomas, a world renowned expert on the history of the gas industry, was commissioned to undertake a study on the history of the former gasworks site and the gasholder. You can download a copy of his A History of the gas industry in Great Yarmouth here:

On 15 July 2025, he also gave a talk at the Time and Tide Museum in Great Yarmouth. You can watch a recording of his talk and view the presentation here:

Updates

Site neighbours will be kept up to date via letters, and we encourage the wider community to access updates via this website. Anyone with any questions can contact our community relations team via the contact section at the foot of this page.

Community visits

We welcomed local residents to site on 27 November 2024 to learn more about the gasholder and our work.

During these visits the team met George Tovell who worked on the gasworks when he was just 16 years old. In April 2025, we invited him back to share some of his memories.

T-Level Engineering students from East Coast College also visited site in February and March 2025.

Two groups from the University of the Third Age (u3a) also had tours in March 2025.

Organisations close to the work can also apply for funding through the Community Grant Programme, please get in touch for more information.

Online record

As work progresses, this section will provide an online record of the work and all documents released publicly about the project.

Download Historic Building report

Images

Contact us

If you have any questions about our work, you can contact a member of our community relations team by:

Email: [email protected]

Phone: 020 7323 3544

(between 9am and 5pm Monday to Friday, or leave a voicemail and we will return your call)

Freepost: RTBU-HAYY-LCUX 7 Bayley Street, London WC1B 3HB

(no stamp required)