National Grid Electricity Transmission (NGET) has been successful in securing £8.12m of funding from Ofgem’s Network Innovation Competition (NIC) to research the uprating of overhead lines (OHL), with the remainder being funded by National Grid.

RICA will provide a faster option to alleviate network constraints through uprating existing 275kV lines to 400kV, delivering significant savings to consumers. Our Core scenario estimates £286m of savings can be delivered to consumers.

Uprating will increase the efficiency of transmission infrastructure through lower losses, saving energy and cost. In the near future where GB’s electricity supply still contains a significant carbon content, lower losses will reduce transmission network CO2 emissions. Using RICA will further decrease emissions through avoiding use of steel and concrete required for new OHL builds. RICAs can deliver a 39kt reduction of net carbon emissions by 2050.

Additionally, using RICAs on existing towers to uprate OHLs will reduce the disruption to land and environment that would likely be required if new towers and new foundations were used instead along existing routes, and will prevent new routes being developed in greenfield or brownfield sites.

The project will deliver type-registered RICA designs for use with key 275kV tower types that aren’t inherently upgradable to 400kV on the NGET network - these represent 30% of all 275kV towers. This demonstrates this technology can be rolled out across the network to deliver value for consumers.

Innovation progress

Preparatory works have been undertaken at the Deeside Centre for Innovation (DCI) for the testing and evaluation of RICAs beyond the usual Type Registration (TR) requirements. A concrete footing has been provided, and a custom RICA testing tower has been procured. The installation of the RICAs on the tower is scheduled for completion in June 2025.

The intention is to subject any proposed RICA for installation on the National Grid (NG) System to conditions that closely resemble those of a harsh and polluted environment. It is hoped that this approach will provide additional information and confidence in the overall performance of the RICA design, beyond the Type Registration requirements.

- Double V design established

- RICA design will be modelled using PLS CADD\PLS Tower TM and Finite Element Analysis (FEA) for suitability

- Once modelled and evaluated, construction of physical prototypes for testing and evaluation has been undertaken

A data logging system has been developed and is currently under test and evaluation at the Deeside Centre for Innovation (DCI). One meteorological unit is attached to a fixed mast outside the offices, with assorted sensors and transducers mounted at the top. A second trailer-mounted version is used for comparison around the DCI site. The data being logged includes:

- Air pressure

- Air temperature

- Relative humidity

- Wind speed

- Wind direction

- Rainfall rates

- Solar radiation

The data from both units will be invaluable in building an environmental profile for the RICAs. Two glass rods are also provided to obtain measurements of the level of surface conductivity expected on the surface of high-voltage insulators mounted in North-South (N-S) and East-West (E-W) directions. The units can be mains-powered or battery-powered. The battery option can be further extended by using a solar panel, making the units stand-alone from a power perspective. The data can be collected remotely.

Once these units, along with their transducers and sensors, have been evaluated, they can be installed in battery-powered units complete with solar panels for deployment on towers along the overhead line (OHL) route identified for RICA installation, thus allowing real-time monitoring. This system monitoring, coupled with the performance monitoring conducted at DCI, should allow for the prediction of any likely performance issues. This real-time monitoring of the performance of the “to be installed” RICAs, along with the data captured at DCI over several years, will provide a good understanding of likely real-time “System” performance. To complete the meteorological units discussed above, beyond normal BaU monitoring for RICA leakage current is required.

A sophisticated leakage current monitoring system has been developed within the NG RICA project team and the University of Manchester (UoM). The leakage current monitoring will be incorporated within the tower-mounted monitoring system and will measure currents, in real time, flowing across the composite insulators that make up the RICA assemblies. The aim of this testing, which is beyond Type Registration, is to provide advance notice of any potential actual system issues once RICAs are deployed. This “look ahead” testing will allow time for a measured and considered strategy to be developed and adopted, if required. This strategy may be years in advance of any issues presenting themselves and impacting the actual National Grid overhead line system installations.

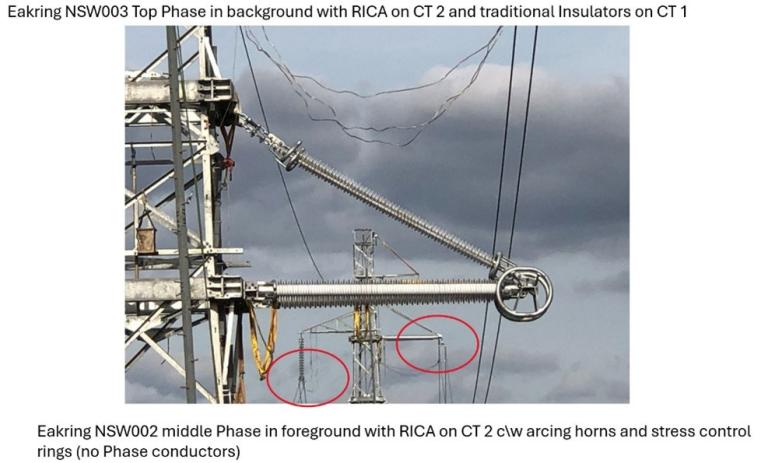

In 2024, the construction of an overhead development and training line at Eakring was completed. This training route allows for the initial development and demonstration of RICA procedures. A secondary benefit is that the route allows training to be undertaken at a representative scale in the field, on a non-energised line, providing an ideal training platform for future RICA installations on the network. This was done in three stages: Foundation Works, Tower Construction, and Tower Wiring.

Foundation works and Tower constructions

Wiring

The circuits of both top phases are strung with twin Upas (2 x 300mm2, AAAC) which is the predominate configuration for L3 & L66 routes, operating at 275kV found on the NG System Network.

The following components are available for development and demonstration activities at the NG training facility at Eakring:

- 12 complete suspension RICA assemblies, complete with fittings. This is a fixed design for all suspension towers.

- Earthwire peak extension steelwork for both L3 and L66 (c) suspension towers. This is a fixed design for all suspension towers.

- Prototype L3 interface steelwork for the bottom, middle, and top phases. This interface steelwork will be redesigned following development and demonstration activities in the first quarter of 2025.

- Prototype L66 interface steelwork for the middle and top phases. This interface steelwork will also be redesigned following development and demonstration activities in the first quarter of 2025.

Plan to BaU

A few of the major steps outlining the transition of the RICA solution to BaU are outlined below:

Type Registration - A program for Type Registration (TR) activities has been produced, detailing components, requirements, and independent, accredited High Voltage (HV) laboratories identified for conducting the required tests.

NGET Processes and Procedures For RICA – In addition to the technical specifications, installation processes, and procedures detailed above, efforts are being undertaken to produce a Technical Guidance Note (TGN) and update the investment case. The TGN is intended as guidance on the implementation considerations, pitfalls, and overall RICA project findings. It is hoped that this TGN will allow power system engineers, scheme developers, etc., to comprehend and appreciate the requirements for RICA implementation on the NG System going forward. The investment case is currently being updated with three overhead line route scenarios, implementing RICA versus rebuilding with a traditional 400kV L8 route construction (current anticipated completion in December 2025).

Detailed Uprate Methodology & Final Investment Case –This is currently ongoing to include technical specifications, installation processes and procedures, Technical Guidance Note (TGN), and updated investment case (current anticipated completion in December 2025).