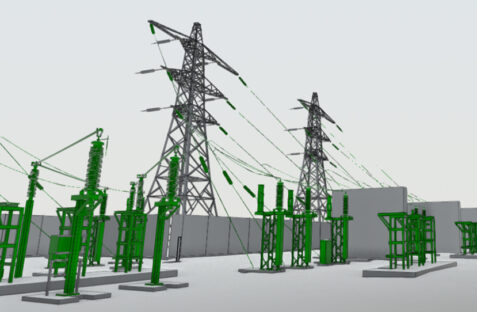

Seabank virtual 3D model created

Digital innovation supports complex task planning

A 3D model of Seabank Substation – the most northerly element of the Hinkley Connection – has been created by National Grid contractor J Murphy and Sons. This will mean planned cable ducting methods which are required to connect Seabank to the new high voltage energy line can be simulated before works begin on site. The model will inform the preparation of method statements and risk assessments required for construction within a live substation.

“We’re working within a live substation around a number of existing services – it’s hugely complex so to be able ‘move around’ the substation virtually before going on site is a huge benefit. The model will improve the quality and safety works such as underground ducting, high voltage cable installation, scaffold erection and dismantling and termination works within the substation”, says Brendan Rowlands, Engineering Manager at J Murphy and Sons.

All new substations are designed using specialist engineering software such as Revit, which is used to model shapes, structure and systems in 3D with parametric accuracy and precision. Seabank however, was not designed in this way and so a virtual version of the substation didn’t exist. To create the model, a laser scan was processed into the software to make sure the dimensions were accurate.

The model will allow the design teams to take their site-based colleagues through the planned method of complex tasks in a classroom environment ahead of works beginning within the substation in Seabank substation. Any changes to the method will be updated in the design and temporary works which will then be incorporated into the model.

James Goode, Project Director for the Hinkley Connection Project, commented: “3D modelling is changing the face of delivery on the Hinkley Connection Project. It is helping us to drive cost and time efficiencies and – most importantly – improve safety for our teams.”