Enabling works - how do we facilitate connections?

Enabling works

As more connections are made to our high-voltage electricity system, upgrades are needed to ensure the network can safely and efficiently meet rising demand.

In England and Wales, our largely interconnected circuits, typically operating at 275kV and 400kV, have equipment rated to specific capacity limits. When new connections seek to import or export additional energy, these limits may be exceeded, triggering the need for upgrades. This process is known as Enabling Works. In this article, we explore the types of work involved in boosting circuit capacity to accommodate the growing number of connections in the pipeline.

Increasing thermal rating - reconductoring overhead line (OHL) circuits

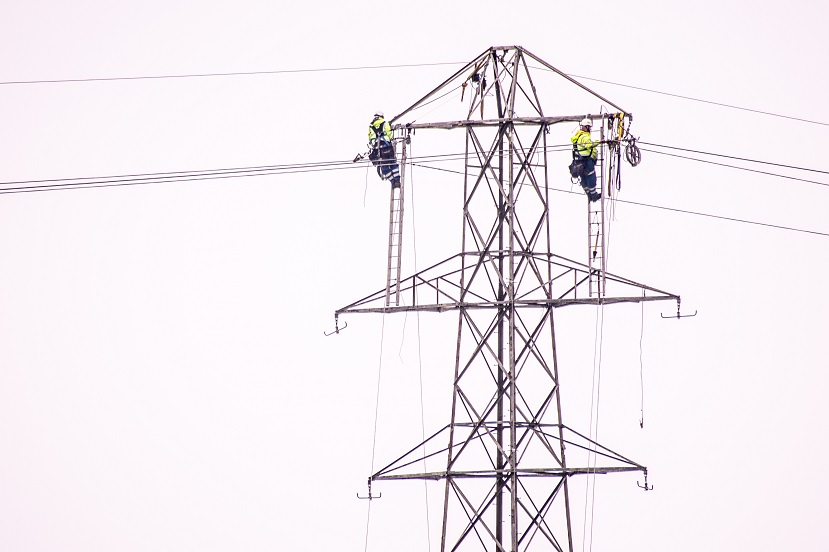

To carry more power safely, we sometimes need to upgrade the conductors on our overhead lines. These conductors, which are metal strands woven together, have a thermal rating that limits how much electricity they can carry before overheating. Excess heat causes the metal to expand and sag, which can breach safety clearances.

To prevent overheating and maintain safety, we can replace existing conductors with larger or more advanced alternatives. These newer conductors often use materials like carbon cores or include air gaps to improve cooling and reduce sag. If these conductors have increased weight, we may require upgrades to towers (also known as pylons), which are carefully engineered to account for conductor weight, foundation conditions, and weather forces. Strengthening may involve steel reinforcements or repainting to prevent corrosion. In some cases, older routes need full design reassessment. Substation equipment, such as transformers and cooling systems, must also be upgraded to handle the extra load and keep performance reliable.

Reactive power compensation

To keep the grid stable, we use reactive power compensation - tools like shunt reactors, series reactors, and synchronous compensators, which help manage voltage. Some reduce overvoltage to protect equipment; others boost voltage to support supply during dips. With renewables fluctuating based on weather, these systems kick in automatically when voltage strays, ensuring safe, reliable power - even under varied loads.

Protection upgrades

Upgrading protection systems is essential to keeping the network safe and resilient. Computer systems located at the end of each circuit (usually within substations) monitor power flow and trigger circuit breakers or isolators if either the voltage or current increases or drops suddenly. Some circuits have smart isolation, meaning faults in one area won’t affect the rest. These systems can even auto-reconnect after a certain amount of time, for example, a falling tree branch might strike a conductor and cause a temporary fault. If reconnection fails, an engineer is alerted to investigate.

New circuits or substations

When existing upgrades aren’t enough, or the increase in demand is too great for the current system, we may need to install new circuits or build new substations. These major enhancements ensure the network can handle increased connections and power flow safely. Before moving ahead, we carry out detailed assessments and full siting studies to confirm feasibility and minimise impact.