Net Zero know-how: Testing the future of energy

From a dramatically reduced carbon footprint concrete to renewable heat pump networks, capable of heating 10,000 homes without home boiler disruption, our Innovation team is focusing its academic skills, engineering experience and problem-solving curiosity on building a clean energy future for us all.

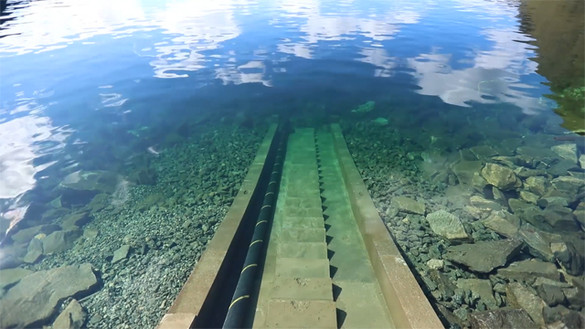

The Deeside Centre for Innovation is in its final year of construction, ready to open its doors in October 2021. It will be a state-of-the-art test centre and creative collaboration hub to UK and worldwide academics, low-carbon start-ups, utility companies and equipment manufacturers.

The ambition is for Deeside to become a globally recognised centre for innovations and collaborations in all green technologies. Deeside’s role in speeding up carbon-free and cost-saving technology is expected to save households and businesses £300m by 2050.

Testing without risk

Deeside is the first test centre in Europe where innovations can be tested to voltages of up to 600 kV at an off-grid substation, bridging the gap between laboratory testing and installation in a connected and operational substation.

This unique off-grid but realistic environment means, says Deeside’s Innovation Manager Alexander Yanushkevich, that “we can accelerate innovation across the energy sector, like testing hydrogen as a renewable alternative to gas and investigating energy storage for renewables.

“It’s revolutionary to be able to trial innovative energy solutions to climate change without putting any operational substation at safety risk, nor affecting the continued supply of electricity.”

Coronavirus lockdowns and the removal of 12,000 tons of contaminated soil beneath the original structure – a decommissioned substation in Flintshire, North Wales – may have put back the official 19-acre test centre opening to next year, but the refurbished Innovation Centre is already the hub for our Innovation team.

A small, smart team

“We’re a small team of 15 people, most of us with PhDs in Engineering, but with very diverse skills and backgrounds,” says Innovation Engineer, Mingyu Sun, whose current research project is looking into how EVs could dynamically charge while on the move. “We’re not just project managers, but technical leads too.”

The projects range from those that will increase the lifetime and reliability of our own assets – weather-proofing steel pylons, for example – to integrating renewable energy into our everyday lives. All have the potential to change the way we live in the future and our effect on the planet.

Innovative home heating solutions

At 37%, heating accounts for the largest proportion of UK greenhouse gas emissions, so tackling how we keep our homes and businesses warm is vital to achieve the UK’s ambition of reaching net zero by 2050.

Innovation Engineer Linwei Chen is leading a project with the University of Manchester to forecast future decarbonised electricity demands and propose solutions – one of which is a district heating network for households with high heat density in Greater Manchester.

“Home heat pumps operate like a reverse refrigerator, extracting heat from the air or ground, but they are bigger than a traditional boiler so there are space constraints,” explains Linwei.

“With our project for a district network connecting distribution pipelines to home radiators, there would be no space issues with small flats and it would be a cost-effective solution to achieve net-zero for heating in cities.”

Heat transformers, hydrogen, construction and more…

Alexander gives a whirlwind tour of some of the current trial projects, due to be showcased at conferences; including the 2020 Energy Networks Innovation Conference and Utility Week Live 2021.

-

A new patented concrete mixture called CemFree, which has a carbon footprint of 80% less than conventional types. Using this concrete in the construction of just our own electricity transmission substations would be equivalent to removing 1,000 carbon-emitting cars from British roads every year.

-

Creating an exact virtual reality replica of the Deeside Innovation Centre, so anyone can experience walking around a real high-voltage substation. This virtual model can be used to train people in a safe environment – particularly important during COVID restrictions.

-

Designing and testing a system that can recover heat generated by transformer losses. We have over 1,000 transformers in our system and this previously wasted heat from each transformer could supply heating to over 100 local households or schools, hospitals and public service buildings.

-

Testing hydrogen power-cell solutions to replace our diesel generators used in emergency supply situations. This will not just improve the reliability of the network but also reduce annual carbon emissions equivalent to taking 100 diesel cars off the road, as well as boosting the use of clean energy hydrogen in Britain.